MAK Structures is the ideal partner for sub-contract steel fabrication, offering a seamless and cost-effective solution for fabricators, construction firms, and manufacturers. Our purpose-built facility and experienced workforce ensure precision and efficiency at every stage.

Our Sub-Contract Steel Service

At MAK Structures, we provide trusted and scalable sub-contract steel fabrication services to fabricators, construction firms, and engineering contractors across the UK. Whether you need support with overflow work, specialist equipment, or a full fabrication partner, we act as an extension of your team—delivering consistent quality without compromise.

Working from our purpose-built facility in Wakefield, we handle every stage of the fabrication process in-house, including cutting, drilling, welding, shot blasting, and finishing. This enables us to provide a seamless, responsive service that helps you stay on schedule and within budget—while maintaining full control over your project standards.

Our experienced, BS EN ISO 9601-1 coded welders and UKCA Marking processes (up to Execution Class 3) ensure every job is delivered with technical excellence, full compliance, and exceptional attention to detail. With a strong track record of on-time delivery, flexible capacity, and professional support, MAK Structures is the sub-contract fabrication partner you can rely on.

1

Precision Cutting & Drilling

Our facility is equipped with the KALTENBACH KBS 1001 saw and KD 1015 drill line, offering automated and highly accurate cutting and drilling of structural steel. This ensures flawless component preparation, helping you avoid delays and rework further down the line.

2

Welding & Fabrication

All welding and fabrication work is carried out by our qualified, coded welders, using UKCA Marking processes up to Execution Class 3. We build everything to spec with a focus on strength, durability, and consistency. Ideal for companies looking to outsource to a team that upholds their reputation.

3

Shot Blasting & Surface Preparation

Using our GIETART GW15004 shot blasting machine, we provide high-quality surface treatment that removes mill scale, rust, and contaminants. This prepares the steel for primer application or final coating and ensures long-term corrosion protection.

4

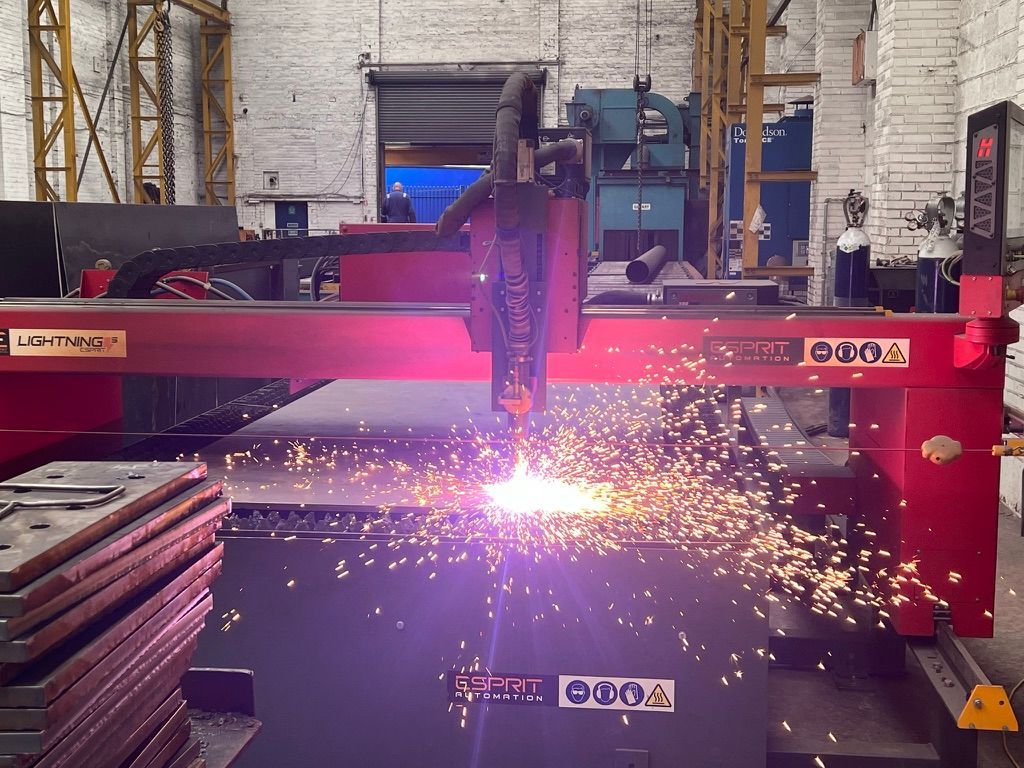

Profiles

Our Esprit Lightning CNC plasma machine, powered by an XPR 300 unit, allows us to cut fittings from 3mm to 50mm thick, tailored precisely to meet the needs of any project.

Why MAK Structures?

We offer a fully integrated fabrication service, covering everything from raw material preparation to cutting, welding, shot blasting, and painting. By managing every stage in-house, we eliminate delays and deliver consistent, high-quality results that meet your exact specifications, freeing you to focus on your core operations.

End-to-End Sub-Contract Fabrication

With a 20,000 sq ft workshop, five overhead cranes, and a 10-tonne single-lift capacity, we’re built to handle high-volume and heavy-duty sub-contract work. Whether you need a short-term solution or ongoing fabrication support, we help you scale your output without stretching your team or resources.

Capacity to Support Your Growth

Using industry-leading equipment like our KALTENBACH saw and drill line and GIETART shot blasting system and our Esprit lighting HD plasma cutter we ensure every component is processed with meticulous accuracy. This precision means fewer issues on-site, smoother project delivery, and peace of mind for you and your clients.

Precision You Can Rely On

All of our welders are BS EN ISO 9601-1 coded, and we operate to UKCA Marking standards up to Execution Class 3. That means you get compliance, safety, and workmanship you can trust—delivered by a team with decades of industry experience and a reputation for getting it right first time.

Certified, Compliant & Consistent

Execution class 3

Our service

At MAK Structures, we offer a full range of steel fabrication services carried out in-house by our skilled team. From preparation to processing and assembly, every stage is handled with precision and care to ensure the highest quality results for your project.

Shot Blasting

Our GIETART shot blasting machine removes rust, scale and surface impurities to prepare steel for finishing. This ensures a clean base that improves durability and protects against corrosion.

Cutting & Drilling

We use precision machinery to cut and drill steel components to your exact specifications. This guarantees accuracy, repeatability and a smooth workflow from processing to assembly.

Welding & Fabrication

Our coded welders and trained platers deliver strong and accurate steel assemblies with full quality control. In-house welding and fabrication ensure reliable turnaround and consistent results.

Painting

Our expert painting service professionally applies high-quality protective coatings to all types of structural steel, ensuring long-term resistance to corrosion, weathering and general wear.

Let’s talk about your project

Looking for a reliable steel fabrication partner? Contact us today to discuss your requirements.

Contact us:

Delivery Address

Unit 11

Mallard Industrial Park

Charles Way

Horbury Junction

Wakefield

WF4 5FD

We will get back to you as soon as possible.

Please try again later.